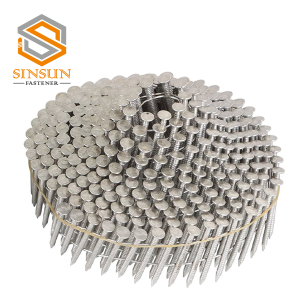

Hot Dipped Galvanized Coil Nails

Product Details of Smooth Shank Wire Coil Nail

Hot-dipped galvanized coil nails are specialized fasteners that are commonly used in various construction and woodworking applications. Here are some key details and uses of hot-dipped galvanized coil nails:Material and Coating: Hot-dipped galvanized coil nails are made of high-quality steel for strength and durability. They are coated with a layer of hot-dipped galvanized zinc to provide excellent corrosion resistance. The galvanized coating helps protect the nails from rust and extends their lifespan.Construction: These nails are manufactured in a coil format, which allows for efficient and continuous fastening. They are typically collated or held together by wire, plastic, or paper strip, making them compatible with coil nail guns or pneumatic nailers.Outdoor Applications: Hot-dipped galvanized coil nails are commonly used in outdoor projects or applications that require excellent resistance against rust and corrosion. They are suitable for outdoor decking, fencing, roofing, siding, framing, and other construction projects where nails may be exposed to the elements.Pressure-Treated Lumber: These nails are preferred for fastening pressure-treated lumber, which is commonly used in outdoor and wet environments. The galvanized coating provides an extra layer of protection, ensuring that the nails do not corrode or damage the pressure-treated wood.Severe Weather Conditions: Hot-dipped galvanized coil nails are also suitable for use in areas with high humidity, coastal regions, or areas prone to heavy rainfall or saltwater exposure. The galvanized coating ensures that the nails remain resistant to corrosion, even in harsh weather conditions.It is important to select the appropriate size and gauge of hot-dipped galvanized coil nails based on the specific application and material thickness. Always adhere to the manufacturer's guidelines and specifications for the most effective and durable results.Note: While hot-dipped galvanized coil nails offer excellent corrosion resistance, they may not be suitable for certain highly corrosive environments or exposure to certain chemicals. In such cases, stainless steel nails or other specialized fasteners may be recommended.

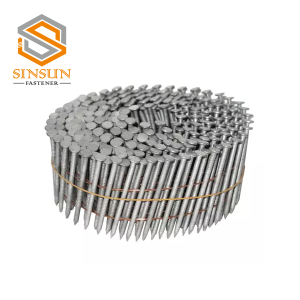

Product show of Galvanized Coil Siding Nail

Galvanized Coil Siding Nail

Hot Dipped Galvanized Coil Nails

Galvanized Coil Nails

Size of 15 Degree Wire Weld Coil Nails

Smooth Shank

Ring Shank

Screw Shank

Product Video of Ring Shank Wire Collated Coil

Galvanized coil nails Application

Galvanized coil nails are commonly used in a variety of construction and woodworking applications. Here are some specific uses for galvanized coil nails:Framing: Galvanized coil nails are often used in framing applications, such as constructing walls, roofs, and floors. The high-quality steel and galvanized coating ensure the nails hold the framing materials together securely and resist corrosion, even in outdoor or humid environments.Decking and Fencing: Galvanized coil nails are ideal for fastening deck boards and fence panels. The galvanized coating protects the nails from moisture and ensures they are suitable for outdoor use. These nails are often used for attaching deck boards to the joists or for securing fence panels to posts.Siding and Trim: When installing siding or trim, galvanized coil nails are commonly used to fasten these materials to the underlying structure. The galvanized coating ensures the nails withstand environmental conditions and prevent rusting or deterioration.Roofing: Galvanized coil nails are used in roofing projects where they secure roof shingles, tiles, or other roofing materials to the roof deck. The galvanized coating provides protection against moisture, which is especially important for roofs that are exposed to rain, snow, or other weather elements.Outdoor Construction: Galvanized coil nails are suitable for various outdoor construction projects, including building sheds, pergolas, gazebos, or other structures. These nails can handle the challenges of outdoor environments and provide long-lasting durability.Pressure-Treated Wood: Galvanized coil nails are commonly used with pressure-treated lumber, which is treated to resist decay and rot. The galvanized coating ensures the nails do not compromise the wood's protective treatment, making them suitable for constructing outdoor structures or using pressure-treated wood for any project.Remember to choose the appropriate size and gauge of galvanized coil nails based on the specific application and material thickness. Always follow the manufacturer's guidelines and recommendations for optimal performance and longevity of the nails.

Wire Collated Smooth Shank Coil Siding Nails Surface Treatment

Bright Finish

Bright fasteners have no coating to protect the steel and are susceptible to corrosion if exposed to high humidity or water. They are not recommended for exterior use or in treated lumber, and only for interior applications where no corrosion protection is needed. Bright fasteners are often used for interior framing, trim and finish applications.

Hot Dip Galvanized (HDG)

Hot dip galvanized fasteners are coated with a layer of Zinc to help protect the steel from corroding. Although hot dip galvanized fasteners will corrode over time as the coating wears, they are generally good for the lifetime of the application. Hot dip galvanized fasteners are generally used for outdoor applications where the fastener is exposed to daily weather conditions such as rain and snow. Areas near the coasts where the salt content in rain water is much higher, should consider Stainless Steel fasteners as salt accelerates the deterioration of the galvanization and will accelerate corrosion.

Electro Galvanized (EG)

Electro Galvanized fasteners have a very thin layer of Zinc that offers some corrosion protection. They are generally used in areas where minimal corrosion protection is needed such as bathrooms, kitchens and other areas that are susceptible to some water or humidity. Roofing nails are electro galvanized because they are generally replaced before the fastener begins to wear and are not exposed to harsh weather conditions if installed properly. Areas near the coasts where salt content in rain water is higher should consider a Hot Dip Galvanized or Stainless Steel fastener.

Stainless Steel (SS)

Stainless steel fasteners offer the best corrosion protection available. The steel may oxidize or rust over time but it will never lose its strength from corrosion. Stainless Steel fasteners can be used for exterior or interior applications and generally come in 304 or 316 stainless steel.