Rivets are an essential component used in various industries for joining two or more materials together. They provide a reliable and durable fastening solution, ensuring structural integrity and strength. There are several types of rivets available, each with its distinct characteristics and applications. In this article, we will explore different types of rivets and their corresponding uses.

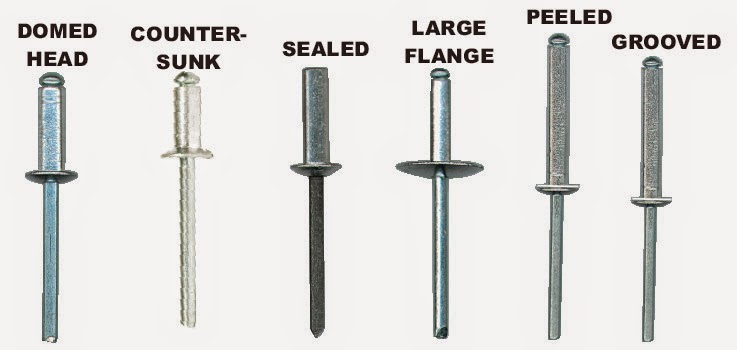

One commonly used type of rivet is the blind rivet, also known as a pop rivet. Blind rivets offer a convenient and efficient fastening solution when access to the backside of the workpiece is limited or completely restricted. These rivets feature an open end type dome head design, making them easily installed using a blind rivet tool. They are widely used in industries such as automotive, aerospace, construction, and manufacturing.

The color paint open end type dome head rivets are a variation of blind rivets that feature a colored head. This characteristic provides an aesthetic appeal and can be utilized in applications where appearance is a crucial factor. These rivets find applications in industries that require a visually appealing finish, such as automotive exterior panels or furniture manufacturing.

Another type that offers both functionality and aesthetic appeal is the polished stainless steel blind rivet. These rivets are well-suited for applications that require corrosion resistance and a polished finish. Industries like marine, architectural, and food processing often utilize polished stainless steel blind rivets in their projects.

For applications that require versatility and adaptability, multi-grip type blind rivets are an ideal choice. These rivets have multiple grip ranges, allowing them to accommodate a broad range of material thicknesses. This characteristic makes them suitable for applications with varying material combinations or thicknesses, providing a secure and dependable fastening solution across industries such as sheet metal fabrication and HVAC installations.

Large flange head pop rivets, as the name suggests, have a large flange or head that provides an increased bearing surface. This larger surface area distributes the load and reduces pressure on the workpiece, making them suitable for applications involving thin or brittle materials. Industries like electronics and signage often use large flange head pop rivets to ensure a secure and durable bond without compromising the integrity of the material.

In conclusion, rivets play a crucial role in various industries, offering a reliable and efficient method of fastening materials together. The blind rivet, color paint open end type dome head rivet, polished stainless steel blind rivet, multi-grip type blind rivet, and large flange head pop rivet are just a few examples of the diverse range of options available. Understanding the characteristics and applications of each type is essential in selecting the most appropriate rivet for a given project.

Post time: Oct-13-2023