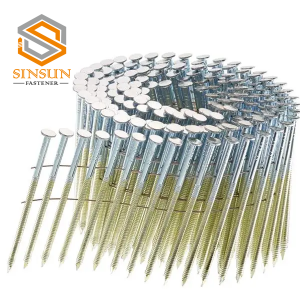

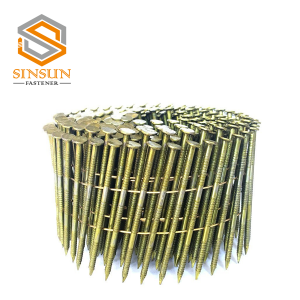

Ring Shank Coil Roofing Nails

Product Details of Ring Shank Coil Roofing Nails

Ring Shank Coil Roofing Nail are nails designed specifically for fastening roofing materials, especially on roofing projects where high wind resistance is required. Here are some features and uses of ring-handled roll roof nails: Shank Design: Ring-shank nails have a series of rings or ridges along the length of the nail. These rings provide enhanced retention, making it difficult to remove the nail once it is driven into the material. The loop shank design is more resistant to loosening and pulling out than nails with smoother or flat shanks. Coil Configuration: Ring-shank roofing nails typically come in a coil configuration. These nails are connected together with a flexible coil, making them suitable for use with a pneumatic coil nailer. The coil design allows for quick and efficient installation of large numbers of nails without the need for frequent reloading. Materials: Ring-handled roll roof nails are typically made from galvanized steel, stainless steel, or aluminum. Material selection depends on the specific roofing application and the level of corrosion resistance required. Length and Gauge: The length and gauge of nails will vary depending on the roofing material and specific project requirements. Typically, they range in length from 3/4 inches to 1 1/2 inches and in sizes 10 to 12. Application: Ring-handled roll roof nails are primarily used to fasten roofing materials such as asphalt shingles, underlayment, roofing felt, and other roofing components. The enhanced holding power of the loop shank design ensures the nails stay securely in place even in high winds and other harsh weather conditions. When using ring-handled roll roofing nails, it is important to follow safety guidelines and use the proper tools, such as a pneumatic nailer. Be sure to refer to the manufacturer's instructions for the specific nails and roofing materials used to ensure proper installation and optimal performance.

Product show of Coil Roofing Ring Shank

Ring shank Collated Coil Nail

Ring Shank Wire Roofing Coil Nails

Wire Collated Ring Shank Coil Framing Nail

Size of Ring Galvanized Coil Roofing Nails

Smooth Shank

Ring Shank

Screw Shank

Product Video of Roofing Nails Ring Shank

Ring Shank Roofing Siding Nails Application

Ring shank coil roofing nails are primarily used for fastening roofing materials, specifically in roof construction and repair projects. Here are some specific uses for ring shank coil roofing nails:Installing Asphalt Shingles: Ring shank coil roofing nails are commonly used to fasten asphalt shingles to the roof deck. The ring shank design provides increased holding power, helping the shingles stay securely in place even during high winds.Attaching Roofing Underlayment: Roofing underlayment, such as felt or synthetic materials, is installed underneath the shingles to provide an additional protective layer. Ring shank coil roofing nails are used to secure the underlayment to the roof deck, ensuring it remains in place during installation and throughout the lifespan of the roof.Securing Roofing Felt: Roofing felt is often applied between the roof deck and shingles to provide an added layer of protection against moisture. Ring shank coil roofing nails are used to fasten the roofing felt to the roof deck, keeping it securely in place.Fastening Ridge Caps and Flashing: Ridge caps, which cover the ridge line of the roof, and flashing, which is used to direct the flow of water away from vulnerable areas, both require secure fastening. Ring shank coil roofing nails are used to attach ridge caps and flashing, ensuring they are firmly anchored to the roof.High Wind Areas: Ring shank coil roofing nails are commonly used in locations where high wind resistance is required. The ring shank design provides additional holding power, reducing the risk of shingles or other roofing materials being lifted or blown off during storms or high winds.Overall, ring shank coil roofing nails are essential for securely fastening roofing materials to ensure the durability and integrity of the roof. They offer enhanced holding power, making them particularly useful in areas prone to high winds and adverse weather conditions.

Wire Collated Galvanized Coil Nail Surface Treatment

Bright Finish

Bright fasteners have no coating to protect the steel and are susceptible to corrosion if exposed to high humidity or water. They are not recommended for exterior use or in treated lumber, and only for interior applications where no corrosion protection is needed. Bright fasteners are often used for interior framing, trim and finish applications.

Hot Dip Galvanized (HDG)

Hot dip galvanized fasteners are coated with a layer of Zinc to help protect the steel from corroding. Although hot dip galvanized fasteners will corrode over time as the coating wears, they are generally good for the lifetime of the application. Hot dip galvanized fasteners are generally used for outdoor applications where the fastener is exposed to daily weather conditions such as rain and snow. Areas near the coasts where the salt content in rain water is much higher, should consider Stainless Steel fasteners as salt accelerates the deterioration of the galvanization and will accelerate corrosion.

Electro Galvanized (EG)

Electro Galvanized fasteners have a very thin layer of Zinc that offers some corrosion protection. They are generally used in areas where minimal corrosion protection is needed such as bathrooms, kitchens and other areas that are susceptible to some water or humidity. Roofing nails are electro galvanized because they are generally replaced before the fastener begins to wear and are not exposed to harsh weather conditions if installed properly. Areas near the coasts where salt content in rain water is higher should consider a Hot Dip Galvanized or Stainless Steel fastener.

Stainless Steel (SS)

Stainless steel fasteners offer the best corrosion protection available. The steel may oxidize or rust over time but it will never lose its strength from corrosion. Stainless Steel fasteners can be used for exterior or interior applications and generally come in 304 or 316 stainless steel.

Package of Roofing Nails Ring Shank